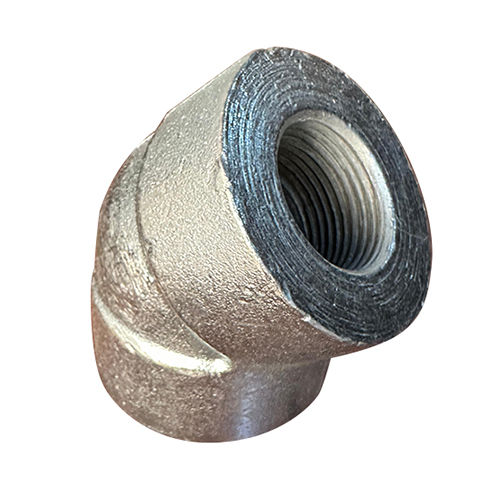

Socket weld pipe fitting

Price 200.0 INR/ Piece

MOQ : 100 Pieces

Socket weld pipe fitting Specification

- Tolerance

- 0.1 mm

- Sealing Type

- Metal-to-metal (with welding)

- Connection Type

- Socket Weld

- Temperature Range

- -20C to +450C

- Thread Type

- Not Applicable (Socket Fit)

- Flexibility

- Rigid

- Diameter

- 6 mm - 100 mm

- Tensile Strength

- 515 MPa (for SS304/316)

- Bend Radius

- As per standard fitting design

- Yield Strength

- 205 MPa (for SS304/316)

- Product Type

- Socket weld pipe fitting

- Material

- Stainless Steel

- Connection

- Socket Weld

- Shape

- Elbow/ Tee/ Coupling (as per requirement)

- Standard

- ASTM A182 / ASME B16.11

- Surface Treatment

- Polished

- Outer Diameter

- 1/8 to 4 (NPS)

- Section Shape

- Round

- Length

- Up to 100 mm (varies with fitting type)

- Thickness

- 3 mm - 12 mm (as per specification)

- Color

- Silver

- Warranty

- Yes

- Usage

- Industrial piping systems

- Rated Pressure

- 2000#, 3000#, 6000# (class rating)

- Material Grade

- SS304 / SS316 / SS316L

- Application

- Chemical, Petrochemical, Oil & Gas, Power Plant, Water Treatment

- Manufacturing Process

- Forged

- Customizability

- Available

- Additional Product Specifications

- Wall Thickness Tolerance

- 12.5%

- Marking

- Size, Grade, Standard and Manufacturers Logo

- Hardness

- 80-100 HRB (Rockwell B, SS304/316)

- Packaging

- Wooden Box / Carton / Customized

- Fire Resistance

- Yes

- Corrosion Resistance

- Excellent

- Lead Time

- 7-15 Days (depending on order size)

- Testing

- Hydrostatic & Non-destructive Testing (NDT)

- Compliance

- MSS-SP-79, MSS-SP-83, MSS-SP-95

- End Finish

- Beveled end (for welding)

- Heat Treatment

- Solution Annealed

Socket weld pipe fitting Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

About Socket weld pipe fitting

Capitalise on the scarce opportunity to secure preeminent socket weld pipe fittings, expertly manufactured for industrial reliability. Our forged stainless steel (SS304/316/316L) fittings deliver spectacular corrosion resistance and fire protection, with beveled ends for seamless welding. Each piece boasts eminent hardness (80-100 HRB), precise wall thickness (12.5%%), and a polished silver finish. Certified to ASTM A182/ASME B16.11 and rigorously tested, these fittings are your deal for mission-critical chemical, petrochemical, and energy applications. Custom shapes and prompt delivery ensure you outperform competitors.

Competitive Edge for Industry Professionals

Socket weld pipe fittings are used by distributors, manufacturers, and traders for constructing robust piping systems in chemical, oil & gas, power, and water treatment industries. Used as elbows, tees, and couplings, they deliver primary competitive advantages such as excellent corrosion resistance, fire safety, and precision engineering. Their compliance with MSS and ASTM standards along with spectacular mechanical properties give your project enduring value, dependability, and a technical edge over alternate solutions.

Sample Supply, Certifications, and Policy Protocol

Samples of socket weld pipe fittings are available upon request to facilitate decision-making for prospective buyers. Each sample holds certifications for MSS-SP-79/83/95 and passes stringent hydrostatic and non-destructive tests. We offer supply of samples at a reasonable asking price, with secure packaging in wooden boxes or cartons. Our sample policy ensures transparency, rapid dispatch, and technical supportgiving you confidence before placing large-volume orders and helping streamline your procurement process.

Competitive Edge for Industry Professionals

Socket weld pipe fittings are used by distributors, manufacturers, and traders for constructing robust piping systems in chemical, oil & gas, power, and water treatment industries. Used as elbows, tees, and couplings, they deliver primary competitive advantages such as excellent corrosion resistance, fire safety, and precision engineering. Their compliance with MSS and ASTM standards along with spectacular mechanical properties give your project enduring value, dependability, and a technical edge over alternate solutions.

Sample Supply, Certifications, and Policy Protocol

Samples of socket weld pipe fittings are available upon request to facilitate decision-making for prospective buyers. Each sample holds certifications for MSS-SP-79/83/95 and passes stringent hydrostatic and non-destructive tests. We offer supply of samples at a reasonable asking price, with secure packaging in wooden boxes or cartons. Our sample policy ensures transparency, rapid dispatch, and technical supportgiving you confidence before placing large-volume orders and helping streamline your procurement process.

Socket weld pipe fittings are high-strength connectors for small-bore piping (typically NPS 2 or smaller) where a pipe is inserted into a recessed "socket" in the fitting (like an elbow, tee, or coupling) and then secured with a fillet weld around the circumference, offering excellent leak integrity and structural strength for critical, high-pressure systems, unlike buttwelds, they're easier to align but require precise fit-up and welding for safety.

Key Features & Description:

- Design: The pipe slides into a socket, creating a strong, leak-proof joint when welded. No beveling of the pipe end is needed.

- Application: Ideal for small pipes (NPS 2 and below) in high-pressure, high-temperature, or hazardous fluid systems (e.g., steam, flammable/toxic chemicals) where leakage is unacceptable.

- Strength: Provides high structural strength, superior to threaded connections, making them great for demanding environments.

- Ease of Use: Simpler alignment than butt welds, as the fitting supports the pipe, reducing the need for temporary tack welds.

- Types: Available as elbows, tees, couplings, unions, caps, etc., in forged steel, stainless steel, and alloy steels, with pressure ratings like Class 3000, 6000, and 9000.

- Welding: Joined with a fillet weld, which doesn't penetrate the pipe bore, and inspected via surface methods (MP, PT).

In Simple Terms:

Imagine a pipe fitting with a hollowed-out end (the socket). You slide the pipe into this socket, then weld around the outside edge where the pipe meets the fitting to create a secure, sealed connection, perfect for when small pipes need to handle serious pressure.

FAQs of Socket weld pipe fitting:

Q: How are socket weld pipe fittings tested for quality and safety?

A: Socket weld pipe fittings undergo hydrostatic and non-destructive testing (NDT) to validate their structural integrity, leak resistance, and compliance with industry standards before packaging and delivery.Q: What is the primary benefit of using these fittings in industrial piping systems?

A: The primary benefit is their excellent corrosion resistance, fire safety, and robust sealing, making them ideal for harsh chemical, petrochemical, power, and water treatment environments.Q: When can I expect delivery after placing my order for socket weld fittings?

A: Lead times typically range from 7 to 15 days, depending on order size and customization requirements. Expedited service may be available upon request.Q: Where are these pipe fittings commonly supplied and used in India?

A: These socket weld pipe fittings are supplied nationwide to industrial piping contractors, distributors, and end-users in chemical, oil & gas, power plants, and water treatment facilities.Q: What manufacturing process ensures the fittings superior strength and finish?

A: A forged manufacturing process followed by solution annealing and precision polishing imparts high tensile strength, durability, and an excellent surface finish.Q: How flexible are the customization options for these fittings?

A: Customizability covers diameter, shape (elbow/tee/coupling), length, and specific marking requirements to meet project or client specifications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Pipe Fitting Category

Pipe Tee

Minimum Order Quantity : 100 Units

Section Shape : Round

Material : Stainless Steel

Product Type : Tee

Color : Silver

Shape : Reducing

45 Degree Pipe Elbow

Minimum Order Quantity : 100 Units

Section Shape : Round

Material : Stainless Steel

Product Type : Elbow

Color : Silver

Shape : Round

Pipe Elbow

Minimum Order Quantity : 100 Units

Section Shape : Round

Material : Stainless Steel

Product Type : Elbow

Color : Silver

Shape : Reducing

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free